Grain Bill Calculations

In this age of West Coast IPAs and East Coast Juicy IPAs, when developing recipes it's easy for home brewers to focus their attention on selecting new and interesting aroma/flavor hop varieties. However, the malt profile is equally important to provide the supporting base underneath those hop flavors. In this post I will share a basic approach to calculating the grain bill for your target beer style. Majority of this post is paraphrased from Chapter 5 of Designing Great Beers by Ray Daniels*.

For your recipe you need to know a few things before calculating the grain bill. Namely, you need to know:

1. Target Gravity (OG) - Assuming that there is a plan for a certain style you can find reference values for pretty much any type of beer on the Beer Judge Certification Program (BJCP) website or in Designing Great Beer (you really need to buy this book if you want to brew beers to style).

2. Target Volume of Finished Beer - Are you just brewing for the weekend or a wedding?

3. Fermentables and Proportions - Again, refer to the style that you are brewing but this will include any extract, sugars, base malt, crystal malt or other adjuncts. The proportions can be referenced from the style guides above or if you are doing your own thing then think about what you want the beer to taste like. For example, if you are shooting for a Rye Pale Ale then you need a base malt at 60-80% which could be 2-row pale malt that would give you a darker color than the same amount of Pilsner malt which would give you a lighter body. The rye malt could be 10-30% depending on how much you want to taste the spicy notes of the rye. The remainder might be used for some crystal/caramel malt for color, or wheat to add head retention and body, or oats to add creaminess to the mouthfeel. Much of this will be a trial-and-error, but having a plan is more effective than just guessing and "shooting-from-the-hip".

4. Efficiency of Extraction - For each ingredient you should know how much fermentable extract (sugar) you can expect from your brewing process. If you are using extract or sugars then you can assume that 100% will be extracted in that pure form. However, if you plan on steeping specialty grains or going all-grain with a full mash then you will not be able to get all of the available sugar in those grains. You need to figure this out for your particular set-up, but between 65-80% is probably not a bad figure to assume.

Once you have those four things figured out we can determine just how much grain you need to buy to hit your targets....

When working with specific gravity it is helpful to use gravity units (GUs). For a specific gravity of 1.062 you simply take the last two decimal places - in this case 62 GUs. With that concept under our belt, we have three steps to calculate our grain bill:

1. Calculate the total extract needed: Let's say that we are brewing 5 gallons of an IPA with a target gravity of 1.062. The total extract is simply the product of the volume and the GUs of the recipe.

5 gallons x 62 GUs = 310 GUs of total gravity

2. Determine extract from each ingredient: Since the proportions are already determined by the recipe this is simply multiplying our total gravity from above with the % of the total grain bill for that ingredient. For our IPA let's say that we have 8 lbs of 2-row base malt, 1 lb of wheat malt, and 1 lb of crystal malt.

2-row malt: (0.80) x 310 GUs = 248 GUs

wheat malt: (0.10) x 310 GUs = 31 GUs

crystal malt: (0.10) x 310 GUs = 31 GUs

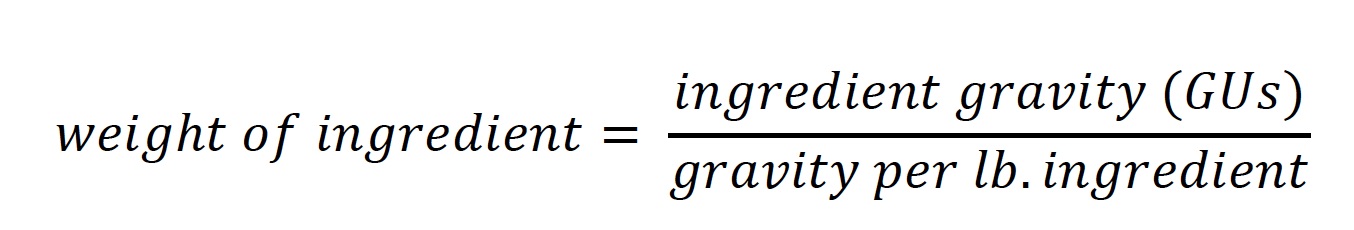

3. Calculate the amount of each ingredient needed: To get the weight of each ingredient we need to divide the extract needed for each ingredient (GUs) by the amount of gravity that can be extracted per pound of the ingredient.

The gravity per lb is based on the efficiency of your brewhouse (65-80% as mentioned previously) as well as the extract potential of the ingredient. If you have access to the malt analysis sheet provided by the maltster then this is basically the hot water extract (HWE) which is a lab test that determines how much sugar you should expect to get from the grain. If you don't have the malt analysis sheet, then you can use a table with extract potential. Designing Great Beer has such a table (Table 5.1, p.31) where the values for different ingredients are given in specific gravity (easily converted to GUs) based on 1 lb of the ingredient in 1 gallon of water. Basically, if water has a specific gravity of 1.000 then when you steep 1 lb of malt in the water what would the expected specific gravity be? In the case of pale malt, we get 1.035 - 1.037 in the table so we choose 36 GUs for that ingredient. Similarly, we find malted wheat to have 38 GUs and crystal malt to have 34 GUs. If we assume a brewhouse efficiency of 70% then we can calculate our grain bill using the above equation:

So you can see that the proportions of malt turn out slightly different than if we were to simply buy our grain based on the proportion in the recipe. Recall that our recipe called for 80% 2-row, and 10% of wheat and crystal malts. Even if we need the same gravity units from both the wheat and crystal (31 GUs), because they have different extract potentials then we actually need slightly different amounts of those malts for our mash.

While all of this can be a little overwhelming, I encourage you to go through these calculations for your next recipe and see if it helps you get closer to the flavor that you are intending. As with anything, the calculations will become easier then more you apply them and you'll start thinking differently about your approach to recipe design. Good luck!

-- Mr. Jackson

Source: Daniels, Ray. Designing Great Beers. Brewers Publications, Boulder. 2000.